When you have identified to saturate areas to give additional protection straightened with wear afterwards it'll extend the existence of this component where it truly is used. There are numerous groups as well as approaches of layers such as for example splashed coverings, cementation coverings, hot-dipped layers, vapor deposition, glasslike enamel coverings, immersion coverings, ceramic finishes, anodic finishes, surface-transformation finishes, powder finishings and so on.

Allow's visit a quick assessment on the numerous finishes:

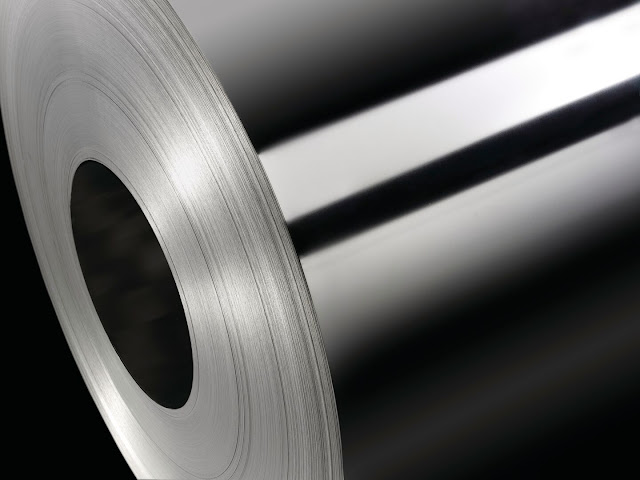

Hot-dipped finishing

In the event that you use hot-dipped coatings of low-melting steels on

the many steel items afterwards it uses cost-effective security with

their locations. If the dirt absolutely free job done thoroughly after

that it really is soaked up in a soften drench of the metal coating.

The metal covering includes a lean alloy coating jointly with a very

pure metallic covering that stick to the function as it is remote

control from the saturate.

Splashed covering

Splashed layer allows the exterior layer of a mass steel structure to

get decreasing resistance and building the messy equipment parts for

revival, adequate factor for melting area inside excess of 1650 ° C the

use of rather unrestrained treatments are managed.

Cementation coatings

Cementation finishes are made by transferring of the metallic covering

in to the base metallic. These outdoors finish are experience alloys

producing little dimensional alteration. In this type of covering parts

are put for heat and in speak with powdered material covering and that

spread in to the outside surface area to shape similar to an outside

coating of alloy and also the breadth of the depends upon the hotness of

functioning and also on enough time.

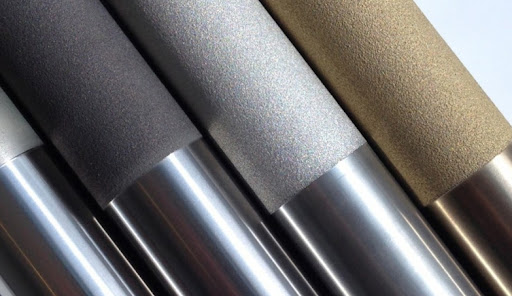

Specular finishing

A slim specular covering is developed on plastics, glass, papers,

metals, yet on products in vapor deposition. The outside layer which is

produced by compression of Metal Coating heavy steam is developed from dissolved

Metal Coating and also by the high-voltage expulsion linking electrodes or a

while from compound methods such as thermal corrosion and also hydrogen

decreased quantity of steel halides.

Immersion layers

These kinds of coatings are produced with using either real method, like

from appropriate compound variation in any other instance from thicker

treatments by way of decreasing electro or aspect much less covering.

Metal Coating ions covering out of resolution in addition to the work section.

The exterior layers are done making use of the other method for instance

from the straight displacement.

Glass like enamel layers

By dropping them with the aid of flow covering the slip could be used.

After leaking it needs to be fired at a greater temperature level which

it mix right into a long-term glass like covering. Generally completely

dry enameling is used for spreadings like tubs and the casting will

certainly be flamed at temperature level then later on the dried powder

of enamel will certainly be spread above the outside surface area where

it socializes.

These coverings are non crystalline coverings for nearly any kind of

appealing lasting support in chemical, practically high-temperature

atmospheres or climatic. Glasslike enamel covering are simple as like

glass. A water arranges a slither deferral of pressed glass, putting on

hold representative, change, non-compliant composite and also coloring

brokers or pacifiers in the drenched enameling.

Comments

Post a Comment